Nearing the 50th anniversary of the novel invention Portadam®, the DNA of our water control technologies, we have commenced the series 50 for 50: Highlighting 50 of our most remarkable, memorable projects while saluting our team, their knowledge, and experience.

Washington, DC, 2001: Our team was brought on to work on the Rainbow Pool as it was integrated as part of the WWII memorial. We created two cofferdams measuring 160’ long and 3’ high and installed 3’ apart, creating a dry construction environment. By diverting the water away from the construction area, we enabled workers to continue operating in a dry environment throughout the process of moving the pool.

Hartsville, SC: One of the most effective ways to protect physical assets from water damage is to divert the streams of water completely away. Increased flood risk comes from multiple variables, some more predictable than others. Once the flood risk is identified, time is a critical factor. Before acquiring a Portadam® solution, Sonoco’s campus experienced disruptive consequences after Hurricane Matthew, which prompted them to look for a rapidly deployed solution. After consultations, reviews, and an extensive site survey, the solution included 5,000 linear feet of barriers at varying heights. The team members received rigorous training on deploying the solution and have thereafter successfully installed the flood mitigation within less than 4 hours, keeping the campus safe away from water.

Santa Clarita, CA: CSI fan, anyone? Behind this image of a submerged car hides the story of a 5-day production, including scientific surveys and testing, ensuring that the thousands of gallons of water remained where needed without any seepage. The scene, used for a nighttime shooting of two separate episodes of the TV show CSI, required the creation of a temporary canal. To achieve this, our team installed two cofferdams back-to-back in a dry, concrete canal that would contain the water safely. Even without movement, the large body of water needed to submerge the car created significant pressure on the structure that contained it, and the frictionless concrete surface posed increased threats to the solution to stand against the hydrostatic pressure of the water without budging. It was through our team’s decades-long understanding of water’s behavior that they were able to safely install the system and successfully maintain the water where it needed to be.

Hanover, PA. One common theme for emergencies is that they usually have far more consequences than imagined. When it comes to water, time is not only of the essence but a crucial factor in understanding the severity of the repercussions. A fire at a fertilizer plant caused harmful chemicals to contaminate the water in a nearby river, immediately affecting its ecosystem and living creatures, including the fish. Given the possible speed at which river currents may flow, contaminations can travel fast and far if not promptly contained. The team was called to the site and, through scientific methods and surveys, collaborating with multiple entities, including the PADEP, to gain insights into what had to be done. Within 24 hours, the team had erected a one-million-gallon basin ready to be filled with the contaminated water, both to prevent further damage while treating the water.

Bishop, California. Being the source of life, water plays a vital role in most ecosystems: where there is life, there is water. The team was called to be a part of the largest water restoration project in the US to date as the Lower Owens River Project commenced. A 62-mile-long stretch of the river and adjacent floodplain had been left dry since 1913 as the river had been diverted into the Los Angeles Aqueduct. In a mission to restore the ecosystem, benefitting biodiversity and threatened and endangered species, the project included re-watering the parts of the river that had been dry for almost a decade. By fully understanding the site, its surroundings, and water’s complex nature, our team was called to the site to be a part of the project by installing a 600’ x 7’ cofferdam, helping to bring the dry river back to life.

Snoqualmie, WA. More than twice as tall as Niagara Falls, Snoqualmie Falls stands at 268 feet high, with a recorded flow up to as high as 45,000 cubic feet per second. The team was brought to the complex site to divert water throughout a repair project of the fall’s hydroelectric plant. The project faced multiple challenges due to the intricate nature of the location. Not only did the solution require the ability to withstand the hydrodynamic pressure, but it further required a solution that could reach up to 10 feet tall. Working with water is always a complex task. Still, situations like this require a complete understanding of not only how to implement a working solution but also how to identify and mitigate the risks that come with the deployment and removal. Thanks to decades of experience and a solution-oriented mindset, our team worked out a solution, combining multiple methods, and could safely and successfully complete the project.

Abu Dhabi, UAE: Called upon by the world’s largest military tradeshow, IDEX, to deploy an 800’ x 35’ x 10’ basin used for the show’s opening in 2015. Our team and equipment were flown to UAE to install the massive pool filled to the top, ready to host a military speed boat race, welcoming the participants to the bi-annual show. Housing a body of water of this size required strict planning and logistics to ensure every step was completed on time. The team was faced with multiple challenges as they assessed the project: Given the purpose of the solution, it had to be able to withstand both the hydrostatic and hydrodynamic pressure that would occur with the movement of the boats. They had to ensure that the solution would remain fixed without any movement, possibly jeopardizing the integrity of the structure. The complex assessment further included considering the external factors, such as the heat of the location and its possible impact on not only the water but also the solution and its black fabric. With our team’s decades-long experience, they made sure that the pool was ready to go on time and stood still and tall throughout the show. Enjoy the time-lapse picturing the set-up

New Orleans, LA: Deepwater Horizon. Portraying an open ocean with a life-size oil rig called for nothing short of a massive body of water. The biographical film, covering the BP oil rig explosion in 2010, required a gigantic pool measuring 325’ x 280’ x 7’, which would house the partially submerged oil rig. The movie itself depicted the nature of the complexity of working with water and the safety risks that are posed by both environmental and chemical factors. Nevertheless, when building a structure of the size needed for the set, safety – a non-negotiable priority of our team- depends on understanding the law of physics ruling water’s behavior. Even the smallest mistake can easily create a domino effect, causing devastating consequences. In fact, for this project, our team was called to the scene after the failure of another solution, which had jeopardized the team’s safety. Our technology was erected and could safely and successfully maintain the water body large enough to be depicted as an ocean on the screen.

Winnibigoshish, MN. Mississippi River: 2340 miles long and one of the world’s most important commercial waterways with the 4th largest watershed, counting for almost a third of the US territory. Due to the topological landscape of the US, almost 60% of the country’s largest rivers, including the Missouri River, merge into the Mississippi or its tributaries, making it a truly complex river system. The flow varies; regardless, it’s deemed to be strong enough to be dangerous for even a skilled swimmer, preventing people from going swimming in the water. Beyond threats visible to the naked eye, the undertows of the river pose one of the more severe risks, further making it a tricky body of water to work with. Our team was called to Winnibigoshish to install a 130′ cofferdam while repairing the dam. After multiple scientific analyses, it was found that the frictionless surface on the riverbed and the undertows would pose challenges to ensuring the system remained static throughout installation and the process. Thanks to our team’s decades-long experience of working with water and the ability to predict and identify any risks proactively, they worked out a solution that let them successfully complete the project.

Central Park, NY: The oldest public park in the United States. The picturesque lake underwent a large restoration in the late 00s, including a substantial removal of the accumulated sediment in the water. The project came with multiple challenges, both through installation and removal. Water is, in itself, a complex compound to control. However, when working on rivers, ponds, or any area where water rests naturally, the surrounding ecosystem needs to be evaluated and understood before getting to work. In this case, the lake rests on a soft, silty benthic zone, which made for an extremely challenging foundation to install any system. Through careful risk mitigation, our team was able to identify the risks that could have jeopardized the success and safety of the system if not addressed. Through their extensive knowledge of working with water, they could provide a solution supporting the framework while stopping it from sinking. Thanks to this, the restoration of the lake could be completed successfully.

Sharpsburg, MD. Each and every site is unique: There is no one site this is the other alike. And some of them are truly one-of-a-kind, irreplaceable historic scenes. In this instance, our team was called to Sharpsburg to divert the water throughout the restoration of the Burnside Bridge, the landmark on the Civil War Antietam National Battlefield. Even though infrastructure, such as bridges, are designed to sustain a lifetime submerged in water, its chemical formula can change the structure of even the most sustainable materials, causing the need for a restoration. Many things can go wrong when working with water, and to have been trusted to work on this historic site is truly a testament to our platinum services backed by extensive water expertise and engineered solutions.

Brunswick, NJ. Some cofferdam projects have been in the works for years: building new bridges, to mention one, is not done over a night. Other projects require an emergency response when time is of the utmost essence. The reasons can be many, but in this case, our team was called to the site at The Delaware and Raritan Canal, during a pipeline installation that had caused a loss of control over the canal. As they had been boring the pipeline under the canal, the machine hit a rock, causing a breach in the canal. Our team was called to the site and could rapidly deploy two cofferdams, gaining back control over the water in the canal and allowing flow throughout the completion of the repair of the critical infrastructure.

Bayonne, NJ. Waves, rising tides, ship wakes, overtopping, and critical infrastructure. This project was nothing short of a challenge. Our team was called to tidal Bayonne Bay during a repair of a pipeline anomaly. This demanding site posed multiple threats, if not at least for human safety. It required an extraordinary understanding of water’s behavior: predicting the unpredictable, including the impact of environmental events and external movements such as ship wakes. The rising tides and waves posed increased hydrodynamic pressure on the solution, requiring the team to be on-site 24/7 for quality control, ensuring the safety of everyone involved. Thanks to their excellent understanding of water and how to control the compound- the project could successfully be completed on time.

Scwhenksville, PA. “It only takes one flood to realize it’s too late.” -Dan DeMeno, Borough Manager, Schwenksville Borough.

Due to its location, Schwenksville is threatened by storms surging from Florida and Georgia, making their way up northeast, bringing more than wind but torrents of rain. They experienced devastating consequences after Hurricane Ida in September 2021, leaving them standing in over 2 feet of water. As the borough was working with FEMA in the aftermath of the hurricane, a mitigation fund was brought to the team’s attention, helping Schwenksville proceed with acquiring a flood protection solution. Portadam was brought to the town for an on-site survey to conduct a thorough assessment to ensure compatibility of the solution and maximum protection of the site.

Nearing the 50th anniversary of the novel invention Portadam®, the DNA of our water control technologies, we have commenced the series 50 for 50: Highlighting 50 of our most remarkable, memorable projects while saluting our team, their knowledge and experience.

Shorewood, IL. The Hammel Woods Dam in the DuPage River had originally been built by Civilian Conservation Corps workers in the 1930s. At the time, the water levels in the river had been much lower and the purpose of installment had been recreational. However, as water levels rose, the low-headed dam became more and more fatally dangerous. The increased water flow caused forceful turbulence and recirculating currents, trapping victims underwater. It’s been called to remove this type of dam across the flatlands in the Midwest as they are known to be deceivingly dangerous. Our team was called to the site, and after careful scientific analysis, they could install the cofferdam to keep the worksite dry throughout the removal. During our team’s decades of experience, they have done multiple projects on low-head dams and know the necessary precautions to ensure safety throughout the projects. Divers are equipped with harnesses with a lifeline and a tender on the bank to pull the diver away if needs be.

Vail, CO. At an elevation of 6000 feet, our team was called to repair the bridge in Grove Creek on Westhaven Drive. Due to a surplus of rocks and boulders on the riverbed, the creek made for a challenging site. The team used their experience and knowledge to divert the water to ensure the project’s success. Creating a temporary channel controlled the water while work was being done with as little disturbance as possible to the river’s ecosystem.

Prospect Park, NY. During a repair of the Boathouse at the NY landmark site Prospect Park, our crew was called to divert water throughout the process. The waterfront building, its patio, and its scenic setting typically attract tourists and are often used for special occasions and weddings. Throughout the project, diverting the water to keep the work area dry is imperative to the success of a cofferdam, and our team goes through multiple rounds to ensure that the waterbed is cleared for the sealing apron to lay as flat as possible. Ensuring successful water work includes countless factors; sometimes, success may depend on factors beyond the water itself, like debris and other obstructions.

Glenrock, WY. High velocity, high risk. Our team was called to a project in the North Platte River during the installment of protection over the existing, active pipelines. Due to the high velocity of water in the river, the project had to be completed through multiple phases to ensure safety from start to end. A diversion dam was initially installed to slow down the flow, allowing the team to deploy the main cofferdam without being swept away.

Laramie, WY. If you look carefully, you can see the crystal-clear water lying on top of the cofferdam skirt. This project in the Laramie River was completed by our team in 1987. A pipeline crossing was in need of repair, requiring a 30” water main installation and temporary, elevated pipes for the water supply while work was being done. By diverting the water with as little disturbance as possible on the waterbed, not only could the team work in a dry environment, but as you can observe, the water could flow peacefully throughout the process as well.

Elizabethtown, TN. Even though many challenges of working with water are directly related to the depth of the body of water, that isn’t always the case. In this instance, our team was called to Elizabethtown for a pipeline anomaly in a creek. The issue at hand wasn’t related to the depth of the water but rather the velocity and layout. Our team needed to divert the fast-flowing body of water, reaching a natural speed of 3-3.5f/s. To expose the pipeline needing repair, they had to clear almost 60% of the river’s width from water, leaving no room for the diversion dam typically used in those instances. With the team’s safety in mind, our team could utilize their extensive water control expertise and experience to complete the project despite the challenging nature of the site.

Kingsport, TN. Another pipeline anomaly called for water control knowledge beyond diversion. A repair on the pipeline parallel to the bank required a dry work area to replace the malfunctioning piece. After multiple thorough analyses, it was decided to use the 7-foot frames to build the cofferdam to ensure its capacity through low and high tides. Each pair of frames this size weighs around 180 lbs. When it was time to deploy, our team had restricted access to the land surrounding the anomaly and had to find another way to get the equipment and cofferdam to the correct location. All frames, liner, and team members had to travel a couple of hundred feet down the river by boat, and all frames had to be placed on tractor inner tubes to be floated down the river. Through our team’s deep understanding of all water aspects, in this case, buoyancy, even the 180lbs frames could be sent down the river relatively easily.

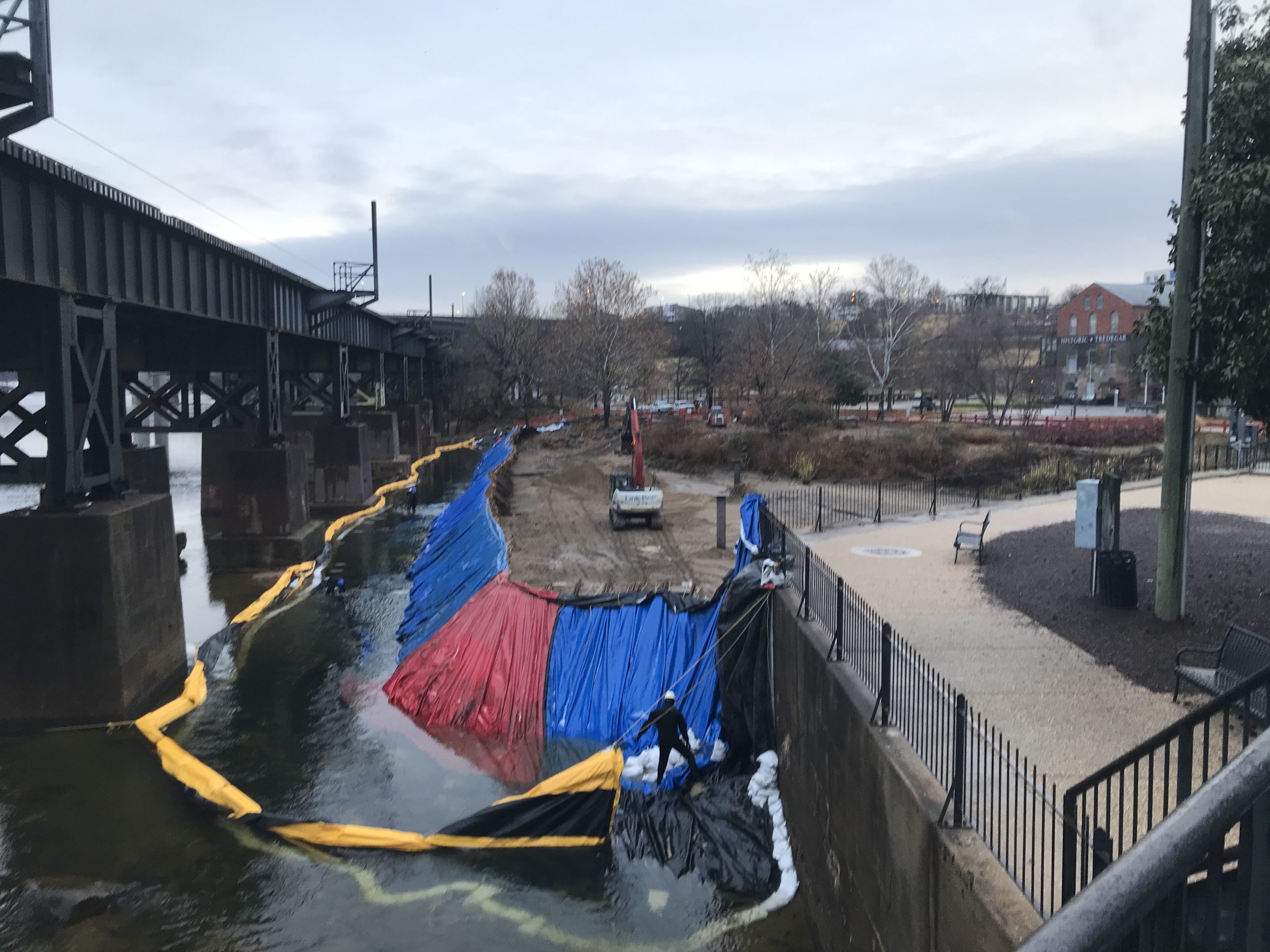

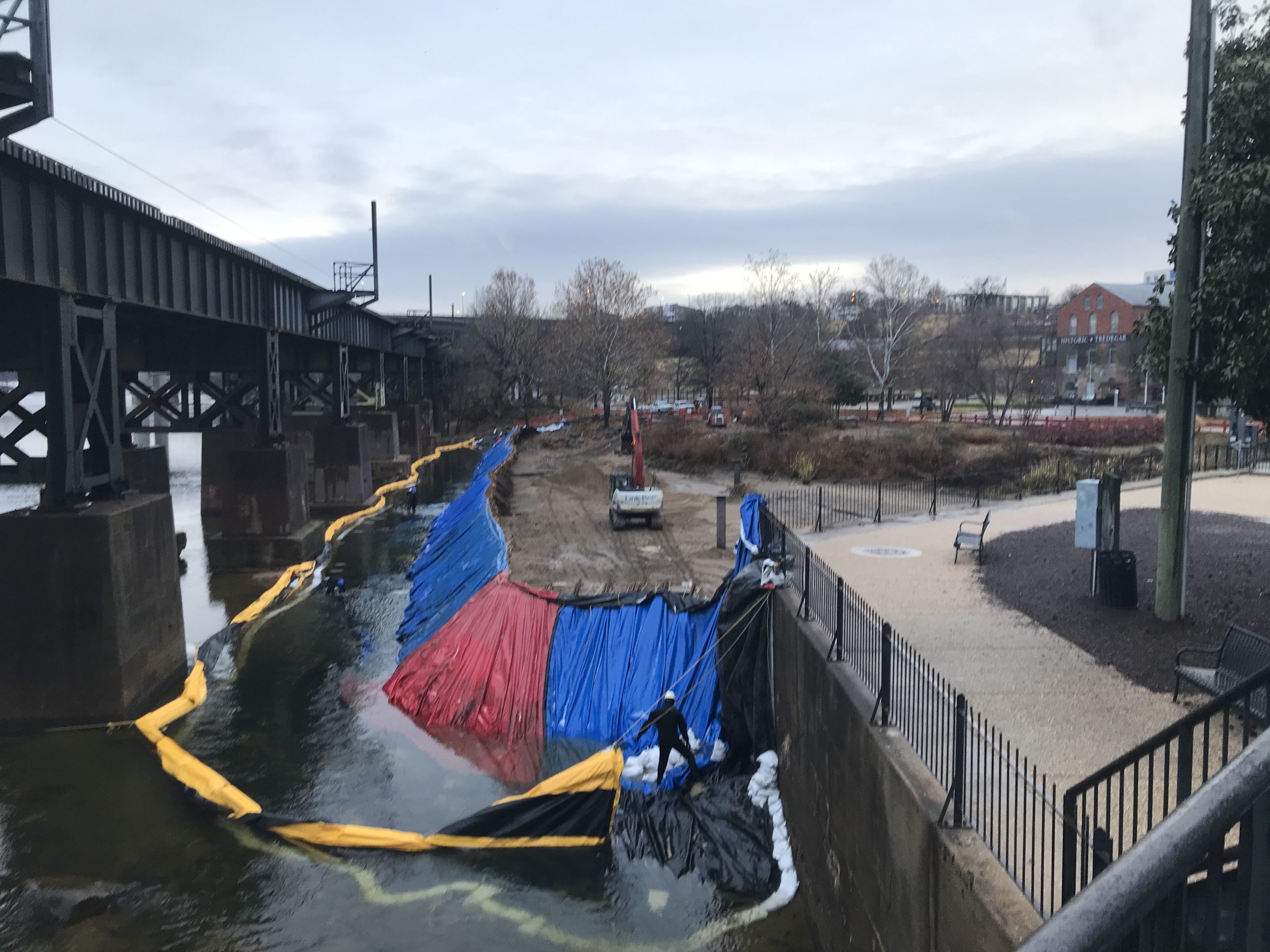

Richmond, VA. The origin of the James River and Kanawha Canal dates back to 1785 when George Washington first initiated the project. Our team was called to the historic canal for sediment removal. After careful evaluation of different options, it was found that a temporary cofferdam would be not only the most cost-efficient but also the most environmentally friendly solution. Predicting and proactively mitigating the significant fluctuations in the height of the water body, the team deployed a solution including 10’ frames, and the excavation project was successfully completed.

Chester Creek, PA. In a remote, natural area in Eastern Pennsylvania, a culvert bridges the gap where Rocky Run outlets into Chester Creek. Our team was called to the site as a passenger rail line running over the culvert was due for rehabilitation. The streambank’s layout and undercut nature posed multiple challenges to the diving team both above and under the water. Due to the presence of underwater obstruction, effectively deploying the water diversion solution depended on the decades-long expertise of our team to analyze and understand the impacts the bank and the obstruction have on the water’s behavior. Thanks to their knowledge, not only could the rehabilitation be completed successfully, but everyone’s safety was ensured throughout the project, and the railroad passengers could continue to travel above the culvert without any worries.

Aspen Park, CO. In early 2020, our team was called to a pond in Aspen during a rehabilitation of an outfall. To cause as little disruption as possible to the waterbody, Portadam’s 12-foot-high, flexible, customizable structure helped the team divert water solely from the area needed dry to complete the project. Due to the increased risk of pollutants or contaminants entering the surrounding water body during the construction activities, it was important to ensure not only the safety of everyone involved but also of the water body, which, thanks to our team’s extensive experience, could be done successfully throughout the project.

Delaware River: the longest undammed river in the Eastern US. A water treatment plant required a replacement of the raw water intake and our team was called to the site. The project was completed in multiple phases, and the engineered Portadam technology was installed to ensure a dry work area as needed to finalize the replacement. Our team was faced with numerous challenges, both due to the nature of the site and the scope of the project. While the permanent water intakes were inactive due to the replacement, a large diameter flume had to be accommodated through the system to provide a temporary water supply until the new intake was fully installed. After a careful and detailed initial analysis and site survey, the team installed a 10’ system due to the fluctuating water levels in the river, averaging between 6-7.9’. Thanks to our teams’ extensive water control expertise, the project could successfully accommodate the flume while ensuring a dry, safe work area.

Louisville, KY. No two projects are ever the same, but some differ more than others. This time, our team was called to the site to solve an unsealable sheet pile cofferdam that was constructed to create a dry work area. The contractor had spent weeks trying to solve the issue, experiencing massive infiltration without any success. Since the sheet piles were set to divert the water body, our team solely deployed our engineered fabric to address the remaining issue at hand. At a depth of 25 feet, our team, including divers, were able to seal the cofferdam successfully by utilizing a custom-built cofferdam wrap, allowing the area to be pumped dry for the project to proceed. Thanks to our team’s extensive water control knowledge, they could work with the contractor to find a unique solution for a unique problem.

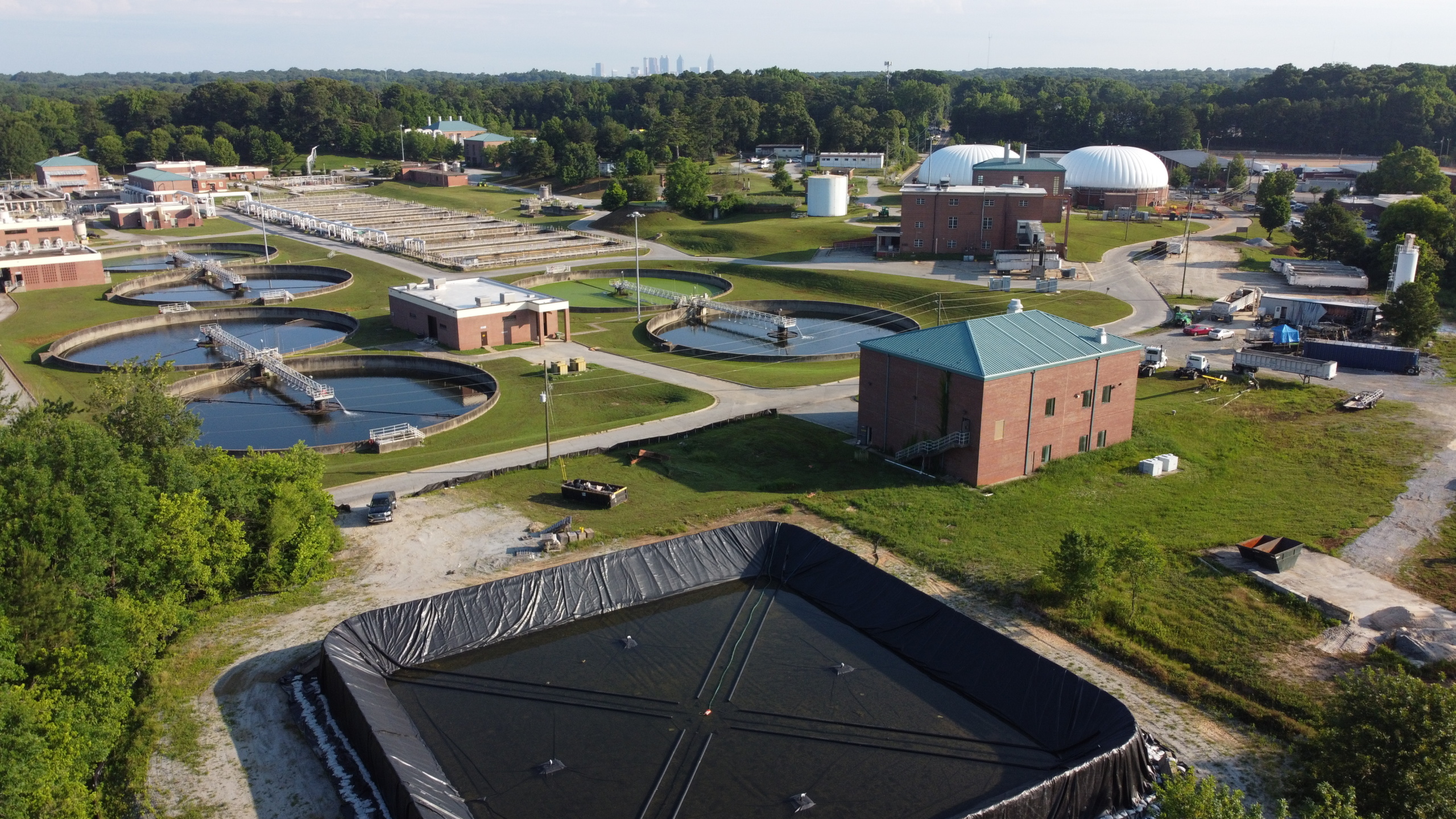

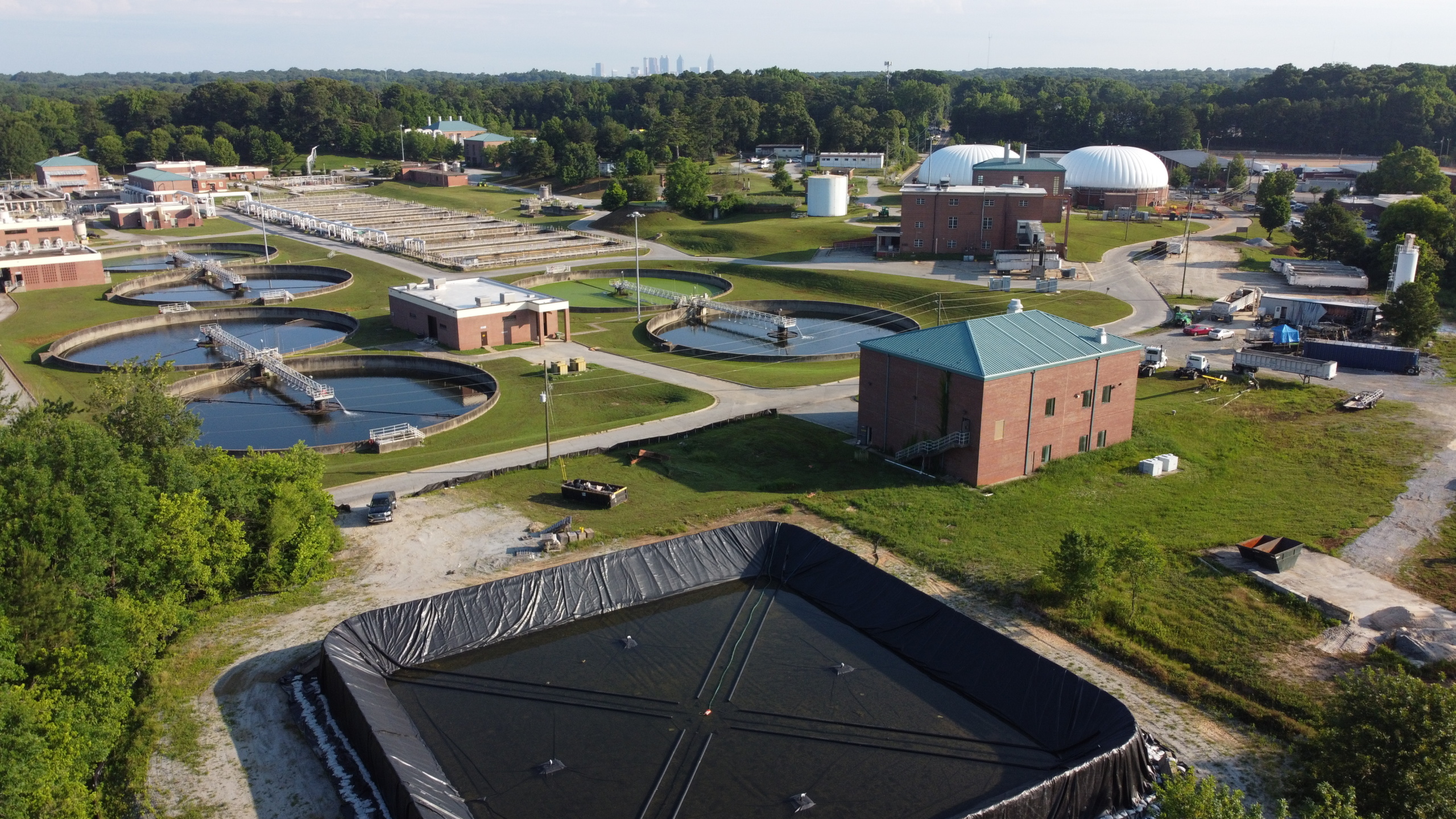

Atlanta, GA. In recent years, the City of Atlanta has undertaken significant upgrades to its water and wastewater treatment facilities, incorporating temporary water storage solutions to ensure seamless transitions. These projects include expanding treatment capacity to accommodate the growing population, retrofitting plants to meet updated environmental regulations, and implementing measures to enhance resilience against extreme weather events like hurricanes and heavy rainfall. Portadam has been instrumental in these efforts, providing innovative and reliable water storage solutions that ensure continuous operation and compliance with stringent standards, enabling Atlanta’s water infrastructure to meet current and future demands.