When you set up sandbags for flood control, you’re creating a barrier that diverts moving water away from a site. Though it doesn’t create a watertight seal, it provides enough of a barrier for many light-risk situations where your barrier only needs to be a few feet tall. As the water flows through the bag, the sand catches the fine particles like silt and clay that come with it, which “fill in the gaps” between the sand to solidify the barrier and prevent water from moving through.

Sandbags used to be made of burlap, but modern bags usually use polypropylene plastic, which can better stand up to abuse from the elements and quick-moving water. You can find more sophisticated bags designed for specific purposes, such as long-term use or filling on contact with water, though they can get expensive.

Although you could fill traditional sandbags with clay or soil in a pinch, sand is ideal because it’s non-porous, meaning it won’t let as much water through. Additionally, sand is lightweight enough for easy assembly but becomes heavy enough when wet to stay in place. An assembled sandbag usually weighs around 40 pounds.

The process of assembling a sandbag barrier is a labor-intensive process — it requires filling up the bags, tying them properly and putting them in the right formation. This might be viable for small barriers, but for larger sites, it becomes costly and hard to accomplish on short notice. Though specialized equipment can automate the filling process, it may not be available right away.

Overall, while a sandbag water barrier may seem like a great solution at first, the details of using them reveal a wide range of problems that more modern solutions can address.

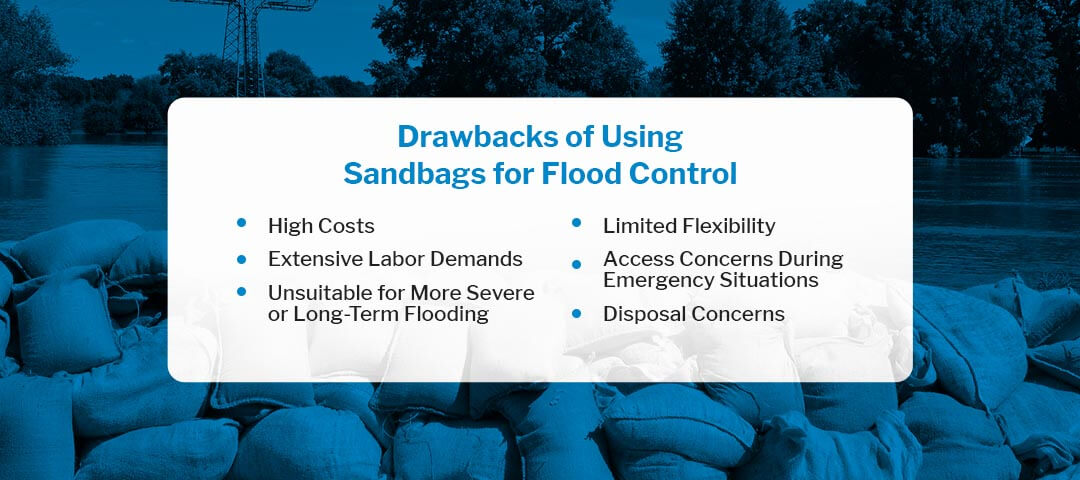

In specific applications, sandbags are often considered an easy-to-use and inexpensive option. However, sandbag flood barriers lose their benefits when you start to scale up. Some of their downsides include:

The equipment for sandbags may be inexpensive, but they call for many labor hours and potential expenses associated with special equipment, disposal and transportation. A 4-foot dike across 150 linear feet would take 11,700 sandbags and 455 man-hours to assemble. Including the costs of recovery, you can expect to pay over $40,000 for this setup.

Labor is a major contributor to those high costs. Sandbags typically can’t come prefilled because of the high costs of transportation and the potential for degradation in storage. Instead, teams need to be filled and assembled on-site. You’ll typically need all hands on deck to get a sandbag barrier implemented quickly in an emergency situation.

Even if you’re not in a time crunch, sandbags can take up valuable time and increase labor expenses.

Sandbags can’t be used in areas that are already flooded or for flood risks with heights of more than a few feet. They also aren’t ideal for ongoing floods because the bags can degrade over time. If you need to install flood protection in the future, you’d need to pay for the whole process again, as most materials used for sandbags aren’t reusable.

Although sandbags can be rearranged into different configurations, they can’t be easily moved. For example, it would likely be cost-prohibitive for a construction company to transport sandbags from a warehouse to a job site. Plus, since they take so long to set up, sandbags may limit your ability to deploy a flood protection solution.

Unless you have a stockpile of materials on hand, using sandbags means you run the risk of not being able to acquire supplies. Before a flood, it might be hard to find sandbags and sand at local stores because other residents of the area have the same plan. Plus, if you’re working with a large area, you could empty out your local stores, leaving many homeowners without a solution.

Most of the cost of using sandbags for flood protection comes from recovery tasks, such as labor, transportation and dump fees. These are necessary considerations because sandbags become contaminated during floods. Floodwater has a wide range of contaminants, from sewage to hazardous waste, so the sand can’t be reused. Proper disposal usually comes with dumping fees.

Because sandbags can be difficult to use and expensive, many flood sandbag alternatives have hit the market, offering more flexibility, simple setup and affordability. As a result, large-scale projects, such as government installations and commercial and construction flood protection, have access to more sophisticated solutions.

Like flood protection sandbags, flexible flood barriers and cofferdams divert the flow of water away from certain areas. Human-made materials, such as highly durable plastics, are erected in an engineered system to surround or block an area, forming a large wall. These solutions are:

The primary drawback for these systems is they need to be set up before a flood risk. Fortunately, with a quick-setup system, you can implement them with less labor and faster than sandbags.

A fillable dam is usually implemented across a body of water but can also be used as a flood mitigation technique. These large barriers are made of a rugged material like plastic or rubber and either inflated or filled with water to increase volume. Choosing the right filler is important because it can affect how the dam behaves and responds to forces, like the pressure of the water’s current.

This option is reusable and affordable, though other factors may depend on the product you choose. Some may be slow to deploy, making them hard to use in emergency situations, and some may offer more or less security for fast-flowing water. Their shapes can vary widely, too, so finding the right one for different sites can be a challenge.

Fillable dams often aren’t as reliable as flood barriers. The many characteristics that affect water movement and the integrity of the dam can make it harder to choose the right kind of dam for the situation and prevent the water from spilling over or breaking through the barrier. When stored, these dams must be folded, and folds can introduce stress points that could cause the dam to fail.

Another option is to use special “sandbags” that can be filled with water or specialty materials that act as a barrier. Some might swell up and form a gel when they contact water, while others may be inflated like a balloon. While they can help you avoid the hassle of acquiring, transporting and disposing of sand, they don’t address the other concerns associated with sandbags. They might be costly, time-consuming to deploy and unsuitable for long-term applications.

Floodproofing can be done with wet or dry techniques.

In dry floodproofing, you can use flood shields or flood panels to create watertight barriers along any openings in the building. They’re often made of materials like steel, aluminum or plastic, with an additional layer of rubber or another material to provide a seal. These panels usually go on the outside of the building to cover up openings in preparation for a flood. They can be applied quickly and don’t require additional space outside the building.

Dry floodproofing can be time-consuming for larger buildings, and it won’t provide protection for any part of the property outside of the building. For example, construction sites can’t use floodproofing methods. Some panels are limited to a few feet of protection, and they typically aren’t suitable for high-velocity flow and waves. This method will also require engineering expertise to ensure the building can withstand the forces of flooding and provide appropriate waterproofing.

Wet floodproofing, on the other hand, allows water to fully enter the building. This strategy requires specific changes to fortify the building against the effects of floods, such as damage-resistant materials and protected electrical systems. The idea is that wet floodproofing eliminates the hydrostatic pressure — the pressure created from water pushing inward on the building — to help preserve the structural integrity of the building. Since water is allowed to flow through, this pressure is minimized, ideally keeping the building in better condition.

The wet floodproofing method will again require engineering expertise and specific plumbing systems to prevent contamination and help with cleanup. This strategy will require some preparation, as you’ll likely need to protect electrical and mechanical systems through means such as elevation, waterproofing and anchoring. Wet floodproofing may also not be appropriate for all zoning laws and requirements or help you reduce insurance premiums.

Unlike the other methods we’ve discussed, levees and floodwalls are permanent solutions that form barriers in the landscape. A levee is typically made of earthen materials like soil, with an impermeable core such as clay. A floodwall is an engineered structure, usually made of reinforced concrete. They can be exceptionally tall and designed in many ways. Due to their strength, they can be very reliable, but no flood protection method is perfect.

Both levees and floodwalls are considerable projects that call for engineering expertise and a long building process. They can’t be removed, either, meaning they can block off certain areas of the property or create other logistical challenges when there is no flood risk. They’re also hard to implement in many settings, such as dense urban locations, small spaces and landscapes that aren’t conducive to the installation. They may not be sufficient to meet floodplain compliance laws and policies, either.

Especially large or tall floodwalls or levees can become cost-prohibitive, with most levees being limited to 6 feet and most floodwalls to 4 feet. Maintenance is another consideration for these permanent structures, as you’ll need to implement a regular schedule to ensure they work as intended.

Our solution for sandbags that fall short was to create an engineered flood barrier. At Portadam, we provide temporary flood risk mitigation structures you can erect quickly and configure to fit any area, from large commercial facilities to construction sites. Our solution has been validated by the U.S. Army Corps of Engineers, which found strong performance across a range of factors like hydrostatic testing, suitability for assembly by unskilled personnel, fill requirements, disposal considerations and adaptability.

Alongside these quality flood barriers and cofferdams, we offer complete flood-fighting solutions with flood risk assessment and analysis services. Supported by an experienced team, Portadam has been delivering reliable flood risk mitigation for decades and can help you find the ideal solution for your site. Reach out to us to learn more about Portadam and start assessing an engineered flood barrier’s suitability for your project.